(1. Guangzhou shiquande Lighting Co., Ltd.; 2. Yueyang Construction Bureau; 3. Yueyang culture and Art Exhibition Center)

[Abstract] the financial crisis originated in the United States has affected the whole world, including our country. The responsible Chinese government has taken a series of measures, including stimulating strong domestic demand to resolve the economic impact caused by the lack of foreign demand, and the construction of cultural venues in many areas of China has been accelerated. Stage lighting system as an important means of visual experience of cultural and artistic facilities, its in-depth design and system engineering are very important. This paper takes Yueyang culture and art exhibition center as an example, discusses the stage lighting system engineering scheme design and equipment debugging experience, for readers' reference.

[Key words] stage lighting, system engineering, deepening design, equipment installation, single machine test, system joint debugging, simulation test run.

Chapter 1 Summary of detailed design

1、 Project overview

Yueyang culture and art exhibition center is a key project of Yueyang City. It is a multi-functional comprehensive building integrating performance, conference, exhibition, film and television, culture and art training. It covers an area of 135 Mu and a building area of 33000 square meters. It can undertake the performance of international first-class cultural groups. It broke the ground on April 26, 2008 and completed the construction task by the end of 2008. The cultural and Art Center has a large theater of 1200 seats and a small theater of 400 seats and its supporting facilities.

The stage lighting system engineering project includes the stage lighting equipment system and related services of a 1200 seat large theater and a 400 seat small theater. The bidding scope includes the provision of a complete set of stage lighting equipment and control system for each theater, as well as the in-depth design, supply, installation, commissioning, personnel training, after-sales service and other related services for completing the construction drawings of all stage lighting systems.

2、 Design objectives

Yueyang culture and Art Exhibition Center, as a developed area with a long history of culture and rapid economic development, lighting system, the main means of visual perception of cultural and artistic facilities, selects products with international and domestic leading technology. In a long period of time in the future, it can also guarantee the vast majority of large-scale conferences and rapidly developing art performances In 10 years, it will not fall behind the audience's appreciation level.

The equipment configuration of stage lighting system engineering of each theater is designed according to the goal of advanced technology, safety and applicability, economic rationality, energy saving and environmental protection, and meets the following requirements:

1. Be able to meet the requirements of large-scale conferences (lectures, reports, exhibitions, demonstrations);

2. It can meet the use requirements of drama and variety show;

3. Be able to undertake the performance requirements of various performing groups and plays at home and abroad;

4. It can meet the requirements of live TV broadcast and program production;

5. The system and equipment reflect the modern advanced level;

6. The intelligent management of equipment operation reflects the characteristics of fast, low consumption and low cost.

3、 Design basis and standard

? tender documents and design drawings for stage lighting equipment of Yueyang culture and Art Exhibition Center;

? code for design of theater buildings (jg57-2000) (j67-2001);

? code for design of lighting system in TV Studio (gy5045-2006);

? lighting requirements for theatres / TV stations / movies (en60598-2-17);

? test and evaluation of optical quality of stage lamps and lanterns (wh-0204-1999);

? photometric testing of projection lighting lamps (GB / t7002-86);

? safety requirements for ventilated Luminaires (GB / t7000.14-2000);

? safety requirements for luminaires for stage lighting, television, film and photography (indoor and outdoor) gb7000.15.2000;

? code for construction and acceptance of electrical installation engineering (GB 50258-96);

? standard for lighting design of civil buildings (GBJ133-90);

? code for electrical design of civil buildings (JGJ / t16-92);

? code for design of low voltage distribution (GB 50054-95);

? general technical conditions for electronic dimming (GB / t13582-92);

? performance parameters and test methods for electronic dimming equipment (GB / t14218-93);

? limits and measurement methods for radio disturbance characteristics of electronic dimming equipment (gb15734-1995?);

? radio disturbance limits and methods of measurement for information technology equipment (gb9254-1998);

? USITT DMX512 (1990) communication protocol.

4、 Design principles

According to the potential use of performance function and the successful examples of modern excellent Convention and Exhibition Center venues, combined with China's stage design practice, the stage lighting system suitable for the special purpose of the center and convenient for domestic and foreign performing groups is selected. Therefore, the design of the system fully embodies the advanced nature, practicality and economy.

1., the advanced nature of the system.

1) A large number of intelligent stage equipments with modern level are used in the system;

2) Intelligent control lighting system;

3) technology intensive between systems reflects the advanced nature of allocation.

4) The system is reliable and can avoid service interruption;

5) Stage lighting equipment adopts digital unified control.

2. Practicability of the system

1) Meet the requirements of short-term rotation of different forms of operation mode;

2) Meet the needs of various types of light consumption;

3) Besides meeting and performance, it can also meet the special needs of TV relay and TV program production.

3. The economy of the system

In the design, the operation management and operation cost factors are infiltrated into each design link. Select advanced technology, energy-saving, environmental protection system equipment, especially a large number of low-power cold beam lamps, which are characterized by high efficiency, low energy, high brightness, low temperature and long life. At the same time, a modern hardware platform is built for the management of the Convention and Exhibition Center, so as to realize the operation goal of high efficiency and low cost.

5、 Design index

1. Illumination index: the vertical illumination of main performance area shall not be lower than 1200lux;

2. Meeting lighting: no less than 550lux;

3. Color rendering index: RA > 92;

4. Color temperature: conventional lamp 3200K ± 150k, special effect lamp 4700k-5600k;

5. Anti interference index of dimming silicon cabinet: higher than the first level standard of "limits and measurement methods of radio disturbance characteristics of electronic dimming equipment";

6. Performance of dimming silicon cabinet: equivalent to European standard, higher than the first level standard of "electronic dimming performance parameters and test methods".

6、 Design content

The stage lighting system of Yueyang culture and Art Exhibition Center, especially the network system, is universal, compatible, forward-looking and the interchangeability of relevant equipment. The design includes five aspects of Yueyang culture and art exhibition center stage lighting system engineering. The contents are as follows:

1. Selection and design of lamps and lanterns for the whole stage lighting system;

2. The selection and design of the whole stage lighting network control system;

3. Selection and design of network control system for auditorium lighting and stage lighting;

4. Stage lighting system strong and weak current pipeline construction, network wiring and stage lighting power distribution system engineering construction organization;

5. Complete product supply of lighting system, deepening design plan of system process, complete supply of equipment and equipment, equipment installation and commissioning, system joint debugging, cooperation test, equipment detection after two years and product warranty within two years, technical personnel training and retraining, performance technical guarantee and product lifetime application technical guarantee.

Chapter 2 stage lighting design

1、 Design features of stage lighting system

Stage lighting design follows the rules of large-scale stage art performance and special use requirements. The 1200 large theater will fully display the stage performance function of Yueyang culture and Art Exhibition Center, mainly for performing large-scale opera and dance (including ballet), performing similar music and dance epics, and receiving famous opera and dance performance groups at home and abroad The ability to undertake major and complex performance projects. At the same time, it can meet the needs of other drama performances, large variety shows, TV recording and broadcasting, and can adapt to the application and management of lighting design and lighting operators at home and abroad. The purpose is to design and configure the lighting process equipment required by various performing arts reproduction process according to the system engineering, so that the stage lighting system can accurately and satisfactorily serve the art exhibition. The characteristics of this design are to focus on the overall reservation of lighting system, abundant storage, flexible and flexible, flexible switching, safe and reliable, providing various forms of stage performance lighting configuration. The system and equipment configuration has the high standard of domestic stage performance lighting

1. Create a full range of conference and stage lighting free space to meet all lighting requirements;

2. In order to make the system run continuously, the reserve and expansion space should be increased appropriately;

3. The anti-interference ability and safety of the system are taken as important design indexes;

4. High efficiency and energy saving cold beam lamps are introduced into the system design;

5. Network digital signal technology is introduced into every link of system design.

2、 Process design requirements of stage lighting system

1. The process design and equipment configuration of the system have the comprehensive use function of the theater, and can rotate the lighting operation design of different dramas in a short time.

2. The design of the system can be quickly converted from one lighting design to another, and the conversion time is completed within 2 hours.

3. The system allows the use of all types of lamps and other supplementary equipment.

4. The design of the system has enough security and storage capacity. The whole system can continuously diagnose and check the console and lighting equipment without interrupting the main power supply.

5. The equipment in the system fully meets the technical requirements for the background noise of the exhibition center stage. In the open state, the noise interference of all lighting equipment and external environment noise is not higher than nr25, and the noise of 1m effect equipment at the test point is not more than 30dB.

6. The expansion capacity of the system is intentionally reserved at the beginning of the system design, such as power silicon control capacity and network capacity. When the funds are sufficient or new technologies appear in the future, the system will not be modified or updated in a large area due to insufficient design, so as to save money and adapt to changes quickly.

3、 Design description of stage lighting system

Description of stage lighting position arrangement:

Advanced and reasonable lighting system configuration, equipped with lamps and equipment with modern scientific and technological level, are the prerequisite for the realization of the overall design goal of stage lighting system in Yueyang culture and Art Exhibition Center. The reasonable allocation of lamps and lamp positions is an important sign to fully reflect the level of lighting design;

The stage lighting is arranged in an omni-directional and three-dimensional distribution. The area light, ear light, column light, side light, reverse side light, top light, top backlight, sky row, ground row, ground light, audience lighting and other locations constitute an omni-directional light distribution array. Each part of the stage has light distribution points, eliminating dead zone, and can be flexibly combined on demand. As shown in the figure below:

Layout plan of stage lighting of 1200 seat Grand Theater

1. Design and configuration of surface lighting system

The surface light is mainly used to illuminate the performance area in the front of the stage, playing a positive role in lighting the performers on the stage, for the modeling of characters or making the objects on the stage present three-dimensional effect;

The new (halogen tungsten) ld750-5750w 5-degree imaging spotlight and ld750-10 750W 10 degree imaging spotlight are used for the surface light. The focusing and light distribution are carried out according to the projection distance to ensure the uniform spot and uniform illumination.

Arrangement and projection method of lamps and lanterns:

Vertical projection: uniform effect under the stage performance area;

Cross projection: enhance the brightness of the center area and depth of the stage;

Key projection: enhance the lighting of local stage performance area.

2. Design and configuration of slap system

The lighting cast from the two sides of the auditorium to the stage is used as the modeling light in the oblique direction of the stage to enhance the three-dimensional sense of the characters and scenery, and form the lighting effect of the front side.

Arrangement and projection method of lamps and lanterns:

The face slap is the auxiliary light of the face light, which is used for character modeling;

The stage color atmosphere can be rendered from one side or both sides;

When the outside lamp and the inner lamp cross project, it can obtain a larger range of projection;

When more than two rows of the same light color are projected at the same time, the high position lamp usually projects the high beam area, while the low position light mainly projects the low light area.

3. Design and configuration of orchestra top lighting system

The lamps and lanterns are hung under the top of the orchestra pit to provide necessary lighting for the performance space on the raised Orchestra stage. The lamps can be installed and configured temporarily according to the performance needs.

4. Design and configuration of column light system

The position of the column lights on both sides of the stage screen line is the column light, and the light from both sides of the stage entrance is directed to the performance area, which is mainly to make up for the deficiency of face light and ear light.

Arrangement and projection method of lamps and lanterns:

The arrangement and projection method of lamps and lanterns are basically the same as that of slap.

5. Top lighting system design and configuration

The top light is set above the stage, and a ceiling lamp is set every 3m-3.5m. The power supply is suspended from the stage ceiling through multi-core cables. Wire baskets containing cables are set on both sides of the lamp suspender. The lamp is hung under the lamp suspender. Its function is to provide necessary lighting for the performance space in depth of the stage. The lamps can be configured according to the performance needs.

Arrangement and projection method of lamps and lanterns:

The first top light is connected with the surface light to illuminate the starring area. When connecting, pay attention to the height of the characters. The first top light can be used as fixed-point light and special effect light, and some lamps can be selected to strengthen the lighting of the fulcrum of the performance area; the second to the eighth can be directly projected to the back of the stage according to the needs of the plot, can also be used as vertical downward projection, or as backlight forward projection, so as to strengthen the stage people Object modeling and scene space lighting. The combination of front and rear lighting makes the stage performance area get more uniform color and brightness. The side lighting of top row lights can enhance the side lighting effect of stage performance area, especially for the left and right sides of the stage, which has a wonderful effect on the shaping of performance characters.

6. Design and configuration of side light system

The role of side light is to create a sense of direction of light source from the side of the stage, which can be used as auxiliary lighting to illuminate the actors' faces, and can strengthen the scene level to model and render the characters and stage space environment. The angle, direction, distance, lamp type, power and other factors will cause different side lighting effects.

Arrangement and projection method of lamps and lanterns:

The shape light from one side or both sides can emphasize and highlight the outline of the side, which is suitable for the performance of relief, figures and other effects with a sense of volume. One side light can show a strong effect of yin and Yang. The double side light can show the splint light with personalized characteristics, but it needs to adjust the light ratio of the front auxiliary light and the side light to obtain a more perfect modeling effect.

7. Design and configuration of lighting system

Sky row lamp is a kind of light casting lamp with astigmatism from top to bottom to cast light on the upper part of the stage sky screen. It is mainly used to express the sky and render the background color.

Lamp arrangement and projection method:

The lamps and lanterns are used in combination with single lamps and arranged in a row. The lighting requires uniform light and is specially used for sky scenery lighting.

8. Design and configuration of ground lighting system

On the contrary, the floor lamp is a kind of light which casts light and colors to the lower part of the stage sky screen from the bottom to the top. It is usually used in combination with the sky lamp to enrich the color change. The lamp is used in combination with single lamp.

Lamp arrangement and projection method:

Rows of lamps and lanterns are evenly placed in front of the stage canopy to reflect the skyline, horizontal line and sunset. They are usually used in combination with the skylight to enrich the light color changes.

9. Design and configuration of rear lighting system

According to the principle of optical imaging and zoom, the lamp can change the size, color, light and shade, virtual and real functions. During the performance, it is installed on a special bracket to follow the actors' movement and enhance the lighting brightness to improve the audience's attention. It can be set in a variety of positions in the theater space, so as to realize the half body, whole body, long distance and small range of actors Lighting effect. Sometimes it can also be used to express abstract and illusory stage plots.

10. Computer lamp design and configuration

The integrated design of intelligent digital computer lamp has higher stability than the mechanized lamp composed of motor frame, spotlight, color changer, shading plate and special color plate. The CMY color mixing system in the computer lamp can call out more than ten thousand kinds of colors, which is incomparable to the general color changer. The replaceable pattern sheet can project various graphics and even slides; when two or more pattern pieces overlap, it can create dynamic images with thousands of changes; the patterned computer lamp can use animation wheel to create movable water shadow, cloud, fire, rock, etc Special effects. The remote control shading board can modify the beam shape, so that the spot can be projected to different scenes and props according to the lighting designer. The same lamp can quickly change the setting to irradiate different objects. The function of the computer lamp is excellent, which can greatly reduce the number of effect lamps on the stage; the computer lamp is mainly arranged on the top light pole above the stage, uses Ethernet to transmit signal, and connects to the computer console through the network node. The functions of lamp projection angle, brightness, transformation plan, beam size, color and other functions can be adjusted arbitrarily, which can fully meet the requirements of various performances for digital computer lamps Change requirements.

11. Design and configuration of ground light system (floor type side light)

The lamps and lanterns placed on the ground or on the bracket can be placed at the corresponding positions of the stage according to the needs of the lighting. The purpose is to strengthen the atmosphere, and the angle can be changed at any time to illuminate the actors and scenery from the side. It is usually placed behind the side curtain of the stage to conceal the lamps.

Arrangement and projection method of lamps and lanterns:

The position of the ground light and the actor's angle basically form 45 ° to 90 ° from the audience position. This kind of light can highlight the surface structure of the object and form the face effect of the object and the person. The light is half light and half dark. The stereoscopic shape of the light projected is strong, giving people a strong sense of perseverance and strength. The others are the same as the side light.

The third chapter is the design of stage lighting control network system

1、 Design orientation and index

1. Design orientation of lighting control network system:

The company adopts advanced science and technology, wide application, international general TCP / IP protocol, Shownet modern high-speed network system supporting DMX512 protocol and can be upgraded to ACN protocol in the future to build a safe, reliable, convenient and practical lighting network in the Convention and Exhibition Center, and all computer-based stage lighting, audience lighting and workplace lighting control systems, including the input and output signals of DMX512 Signal, feedback report signal, manual control, remote control, monitoring signal, video signal, setting function and upgrade function are all transmitted on Ethernet network to realize stage lighting resource sharing and two-way transmission; effectively avoid signal interference and signal attenuation; prevent transmission interruption caused by line fault; facilitate multi-point control and real-time full tracking backup, light remote control and monitoring Control.

2. Design index of lighting control network system:

The main design indexes of lighting system of the project are as follows:

1) Double network and double backup digital lighting control system, working power supply in the network wire rod, the main and standby dimmer fully track backup;

2) Network speed: 1gt bit / S;

3) There are 2000 controllable channels, 1000 groups, 2000 macros, 600 × 99 step lighting effect, 99 lamp databases, 3000 SMPTE events and 9 long-distance videos;

4) The number of controllable attributes such as computer lights and color changers is 2000;

5) Electromagnetic compatibility of dimmer and network node: 50V / M (1m-1ghz);

6) Output power: 6 kW per channel, maximum output voltage adjustable;

7) Three phase input correction: Yes, correction is made after analyzing input power wave type through silicon box processor;

8) Reaction time: 16 ms, which can be adjusted in three levels;

9) Illuminance index: the white light illumination in the main performance area is > 1400lux, which is determined by the actual performance demand;

10) Color rendering index: RA > 92;

11) Color temperature: conventional lamp 3200K, special effect lamp > 4600k;

12) Noise index: the noise caused by the noise of all equipment in the open yard and the noise from the external environment 13) the anti-interference index of the dimmer cabinet: 230US (at 230V);

14) Standard impulse resistance: 100000ic;

15) Dimming cabinet: complete, priority;

16) Trigger accuracy: 16 bit 4000 level;

2、 Control system design

The design of this project adopts the form of double Ethernet carrying the DMX network, which not only meets the demand safely and efficiently, but also lays a good foundation for the future system upgrading, upgrading, capacity expansion and new technology development.

1. Design principle of control system

1) The backbone network equipment shall be the equipment which conforms to the international standard TCP / IP communication transmission protocol and has reliable performance;

2) Double network multi-level backup ensures high-speed and reliable data transmission and sharing;

3) equipment selection requires good reliability, advanced nature, practicality and economy.

4) The console with superior and reliable performance, network learning function, and full tracking and backup support is selected;

5) the distribution of control nodes and the design requirements of the system are advanced, reasonable and forward-looking. It is required to fully consider the different requirements of the performance and adapt to the management and use of lighting designers and operators at home and abroad;

6) The connectors and wires meet the international standards, which are safe, reliable and durable.

2. Design objectives of network system

1) Information interoperability: the network equipment conforms to the international standard network transmission protocol - TCP / IP protocol, light control protocol - DMX512 (1990), which completely solves the problem of network data interoperability;

2) Information interoperability: the designed network devices are network console, network node produced by our company and network equipment in line with international standards produced by international famous companies, which thoroughly solves the problem of interoperability of network data and truly realizes information sharing;

3) Reliability of information: the equipment selected in the design has reliable performance and mature technology. Strand series products have anti error correction function, which makes the transmission data more secure and reliable, and ensures the safe and stable operation of the system. Shownet is a network system with advanced technology and complete functions. It has a set of system management system and effective design measures to prevent various network conflicts. It effectively enhances the practicability and stability of the network

a) Through prediction and information feedback, the fault of equipment is detected in time, and measures are taken quickly to repair the fault, so as to reduce or eliminate network interruption and equipment failure;

b) Redundancy measures should be taken to back up the key equipment online in case of failure of the key equipment. The backup equipment can take over the work immediately without interruption of the performance.

4) Improve the operation quality of the network: using new technology, using reasonable, effective and reliable transmission media, network operation equipment and terminal equipment to ensure the accuracy and fast efficiency of data transmission;

5) Improve the utilization rate of network resources: by fully understanding the signal points needed by the performance, reasonably arrange the lines, so as to maximize the utilization of network signals;

6) System control comprehensiveness: the network system can carry almost all lighting, including stage conventional lights, computer lights, color changers, effectors, field lights, work lights, etc;

7) System scalability: Shownet can be easily extended, expanded and upgraded at any time, compatible with the future ACN protocol.

3. Composition of control network system

Lighting control network system (Ethernet / dmxsignal)

Lighting control network system refers to the network lighting control system. The whole control system strictly follows TCP / IP communication protocol and USITT DMX512 / 1990. The light control system is distributed in star shape, and the signals are concentrated in their respective thyristor chambers. Ethernet nodes are distributed through the hub, and five types of Ethernet signal lines are used for data transmission medium; the dmxs are provided by many sn110 network nodes in the network. Each sn110 has an LCD display to provide information indication and two DMX interfaces. All sn110's working power supply is directly provided from the network by the network cable (the latest international standard IEEE 80203af). All portable network units can be directly connected with the network interface of the wall by plug-in and powered on. Through the strand sn110 node (network node), the Ethernet control signal can be converted to each other, and it can be reasonably distributed in each of the theater's dmxsignal nodes. The lighting network configuration has special network configuration software, which can uniformly configure and modify each information node in the network. The network has Ethernet control, DMX control, wireless remote control, wired remote control, and can access to the field light control system and environmental lighting control system. As shown in the figure below:

Stage lighting control system diagram of 1200 seat Grand Theater

In order to ensure the reliability and stability of the system, we use UPS in each central control room. This uninterruptible power supply (UPS) is an on-line system, which can provide the load with stable frequency, stable voltage and uninterrupted high quality pure sine wave alternating current. The system can effectively overcome the common power quality problems caused by the direct power supply from the external power grid, such as the voltage is too high, too low, the power grid surge or transient spike, the power line clutter interference, power supply interruption or instantaneous power failure, so as to ensure the normal operation of instruments and equipment, prevent the loss of data in the computer and data processing system The design of microcomputer network, minicomputer, workstation and precision electronic instrument is reliable in operation. It can also increase battery pack and extend backup power supply time, so as to meet the special needs of users who can obtain long-term power supply in case of power failure.

4. Network conflict prevention design

1) The emergence of network conflict

At the same time, the open space of our creation inevitably conflicts with each other. In the design, we fully consider any possible causes of system failure when users use them, and provide reasonable and effective preventive measures. The so-called conflict of lighting control network is caused by the configuration conflict of port address caused by the full opening of network port.

2) Network priority judgment prevention design

The key factor of network performance is how to prevent network conflict. Strand Shownet system has a complete set of conflict prevention design:

a) Each device has a unique IP address. After being accessed, these devices will automatically generate an address, which can also be set through the network management software Shownet configuration;

b) Each device can set its control priority level;

c) Each network console has an independent ID number;

d) In order to be more compatible with the control system of work lights / field lights and ambient lighting, a parallel processing program is specially set up for its control system (such as pimea);

According to the above signs, a complete set of judgment mode is formed.

5. Prevention of dimming conflict

1) Multi function setting of dimming control

A strand lighting system, consisting of a computer dimmer control panel and associated processors, can run in the strand Shownet network. The network includes other systems. As long as the dimming loop and the controlled loop are set by HTP, LTP and merge, they can be controlled by more than one system at the same time

a) HTP (high take priority): several signal sources give priority to the high level of brightness level;

b) LTP (latest take precedence): several signal sources output the final brightness level change value;

c) Merge: several signal sources are combined and output according to the level distribution.

Through the setting of the above mode, a single controlled element can be ordered by the above output convention, thus accepting the control of several control elements at the same time.

2) Dimming station identity positioning

The system software of strand computer dimming platform can also ensure that the control conflict of dimming circuit will not occur in the network of multiple systems. Because before the system is started, we have set the IP address of each dimming station to locate its different priority, and make clear the identity of its main console and backup station. Only when the console that the backup station automatically confirms the identity of the "host" fails, it will automatically go online. In addition, in large-scale performances or conferences, the division of labor can be selected through the menu, for example, the host is controlled by traditional lights, and the sub console is controlled by color changer. In the remote control mode, each console has its own independent input command and display, and the data of the control loop can be "partitioned" and recorded. This function allows a console to independently record the control loop on the main cue field, while at the same time, other lighting engineers can use their loops to segment and execute on the same cue field. With its own display and unique loop list, the loop of each console can be divided into any part of the whole system to meet the needs of the stage.

Chapter 4 stage lighting electrical system design

1、 Design basis

1. Lighting scheme provided by lighting designer

2. Relevant national regulations

1) Code for design of theater buildings (jg57-2000) (j67-2001);

2) Code for design of low voltage distribution (GB 50054-95);

3) Code for electrical design of civil buildings (JGJ / T 16-92);

4) Code for design of lightning protection of buildings (GB 50057-94).

2、 Power distribution setting of stage lighting system

1. System index

1) Illumination index: the vertical illumination of main performance area shall not be less than 1500lux;

2) Meeting lighting: no less than 550lux;

3) Color rendering index: RA > 92;

4) Color temperature: conventional lamp 3200K ± 150k, special effect lamp 4700k-5600k;

5) Anti interference index of dimming silicon cabinet: higher than the first level standard of "limits and measurement methods of radio disturbance characteristics of electronic dimming equipment";

6) Performance of dimming silicon cabinet: the same as European standard, higher than the first level standard of "electronic dimming performance parameters and test methods".

2. Stage lighting power configuration

1) 1200 Grand Theater:

a) There are 864 6kW dimming silicon circuits, 192 6kW direct dimming circuits, 19 dimming circuits and 23 straight through circuits for working lights;

b) Total electric power of stage lighting: PE = 6588kw, PJs = 1054.8kw.

2) 400 small theaters:

a) There are 192 6kW dimming silicon circuits, 72 6kW direct dimming circuits and 12 dimming circuits for working lights;

b) Total electric power of stage lighting: PE = 1656kw, PJs = 482kw.

3、 Safety setting of stage lighting electrical equipment in operation

1. Select special transformer

The distribution system adopts three-phase four wire system, and TN-S system is adopted for grounding. When D, yn11 is used as the connection mode group of transformer, this △ / Y0 connection transformer can adapt to three-phase unbalanced load without generating induced electromotive force and loop current. When dimming is performed in the theater, the load and neutral wave shape will be distorted, and the high-order harmonic and zero sequence harmonic currents will generate magnetic flux. Through the iron core, the high-order harmonic and zero sequence harmonic electromotive force will be induced in the primary winding of the transformer through the iron core. The high-order harmonic current flowing through the triangle connected circuit will induce the high-order harmonic and zero sequence harmonic magnetic flux in the primary winding of the transformer with the same size and opposite direction When the full load is adjusted to half load, the high-order harmonic distortion is only 2%, which effectively eliminates the interference caused by voltage wave line distortion. After the zero sequence harmonic potential is greatly reduced, the maximum relative voltage offset is only plus or minus 0.6%, and the power supply quality is significantly improved. Secondly, the △ / Y0 connected transformer can reduce the high-order harmonics and cause little eddy current heating in the core, so the transformer is allowed to operate at full load. The unsymmetrical deviation of output voltage is small, and the distortion rate of power supply voltage waveform is small, which can partly eliminate the mutual interference of dimming equipment. At the same time, the interference of audio and video can also be suppressed. The cross-section area of the zero line is designed reasonably to reduce the phase to phase interference caused by the coupling of the interference signal through the common zero line.

Stage lighting and electroacoustic circuits should be connected from different transformers. If different transformers cannot be used, 1:1 isolation transformer should be used to supply power for sound reinforcement.

2. Reasonably configure the output

Each dimming and straight 6kW output is provided by a 32A socket. The length of three wires in each socket is the same, which is output by stranding.

3. Good grounding

In order to eliminate the interference of silicon controlled rectifier and make audio and video equipment meet the requirements of use, a reasonable and practical grounding system is selected in the lighting system design. The sound reinforcement system and lighting system are equipped with independent grounding trunk line, and the common grounding electrode is adopted, and the grounding resistance is less than or equal to 2 Ω. All power cables and light wires are installed in metal trunking, which is equipped with good grounding device.

4. Electric shock protection

Since most of the lighting distribution lines are connected to the stage lighting through the socket, according to the conventional method of low-voltage distribution system, the socket circuit should be installed with leakage protection for indirect contact protection. Since the leakage switch is easy to misoperate, which directly affects the reliability of the stage lighting system, we adopt the method of wiring PE line with relevant circuit phase lines. In order to reduce the zero sequence impedance and ensure the reliable action of the protection device in case of single-phase grounding fault, so as to ensure personal safety.

5. Lightning protection

Lightning arresters are installed on the low-voltage bus of the substation, and surge protectors are installed in the dimming lighting distribution cabinet to prevent the over-current and over-voltage caused by electromagnetic induction and electrostatic induction when the stage of cultural square or nearby buildings are struck by lightning, which will damage the dimmer cabinet and lighting control computer system, and ensure the safety of dimming silicon cabinet and lighting control calculation system.

4、 Stage lighting electrical cable and line laying

1. The output wires from the silicon cabinet room to all sockets are of the same length by three wires, which are output by stranding. The light lines and audio and video signal lines are far away from each other. When they must meet, they should be crossed at 90 ° with a distance of 0.5m; when they must be parallel, the spacing should be greater than 1m;

2. All signal connecting cables shall be five core shielded wire to prevent interference;

3. There is an independent grounding trunk line. The power cable and light line should be installed in the metal raceway, and the metal raceway should be grounded;

4. The strong current and weak current of the socket box are separated by metal clapboard to avoid the interference of strong current to weak current and ensure the safety of weak current system;

5. Adopt low smoke, flame retardant or fire-resistant copper core cable, and the cable should be able to work at 90 ℃ for a long time, and its service life should be more than 30 years under normal use conditions;

6. The socket box is made of domestic products, and the strong current and weak current in the plug-in box are separated by metal clapboard to ensure safety and facilitate electromagnetic compatibility;

7. Fireproof materials are used for cable tray to prevent cable fire;

8. The bridge or trunking shall be covered and fireproof treatment shall be carried out. The model, voltage, current carrying capacity, cross section, number of cores and sheath of power cable and control cable shall meet the requirements of circuit type, transmission model, service environment and laying mode, and comply with relevant specifications;

9. The control and power cables of moving parts shall be flexible cables meeting fire protection requirements. The laying of cables shall comply with the requirements of GB 50258-96 code for construction inspection and acceptance of 1kV and below wiring engineering of electrical installation engineering;

10. The electromagnetic interference shall be reduced to the minimum during cable laying. When cable hose is used, its length shall not exceed 1 meter. The hanging or sagging flexible cables for power or control lines shall be provided with a stress relief central core wire, and its two ends shall be clamped to release the conductor stress;

11. The core wires of multi-core and shielded cables used in power or control lines are easy to be identified by number. Only cables with less than 25 cores use color code, and the number of cable cores is not identified by cable laying form or sequence;

12. The cable numbers at both ends of each power and control cable shall be the same and marked with a permanent mark with a unique number. The cable number has been indicated in the wiring diagram;

13. The wire should have enough length of cable to meet the requirements of the total travel of relevant equipment, including the travel to the maintenance position. All cable incoming equipment shall be provided with proper incoming connector to facilitate cable replacement. The remaining collecting cable shall be rolled on the cable reel or placed in the equipment and firmly fixed;

14. The box shall be aligned perpendicular to the wall surface during installation, and the vertical deviation shall not be greater than 2mm. The incoming and outgoing wire boxes shall be arranged in order with appropriate allowance. Wires with different circuits, different voltages, AC and DC current in the pipe shall not be threaded into the same pipe. There shall be no joint or distortion in the pipe. When the wire is threaded into the pipe, sheath shall be installed at the outlet to protect the conductor. Before cable laying, carefully check whether there is mechanical loss of cable, and conduct insulation shake test. Power and lighting distribution box installation, its quality standards meet the national electrical engineering construction specifications. The floor power distribution box is firmly installed on the foundation of angle steel or channel steel, fixed with screws, and well grounded. The inlet and outlet pipes are about 10 cm higher than the foundation surface in the foundation. The installation position and size are shown in the drawing requirements, and the rear is installed against the wall without access door. When the floor type power distribution box is installed, the perpendicularity is 1.5mm per meter, and the joint between panels is 2mm. The lighting box is generally installed on the wall, and the project adopts two kinds of installation: light and dark. The concealed wall mounted distribution box can be directly installed in the wall when the wall is built, or holes can be reserved on the wall and then installed. Ensure that the installation is firm, the grounding is good, the installation is flat, straight and the size meets the design requirements, the bottom edge is 1.5m above the ground, the vertical deviation of the lighting distribution box is not greater than 3mm, and the pipeline in and out of the distribution box is allocated to the distribution box and fixed with pipe cap and lock nut. When installing the distribution box, the surface of the cover plate is as flat as the painting layer, and the pipelines in and out of the box are laid in a concealed way.

5、 Stage lighting electrical equipment cabinet setting

1. Structure

The cabinet and frame of electrical equipment are made of anti rust metal and steel plate, and reinforced with steel plate or section steel cabinet frame if necessary. Dust and moisture proof measures shall be taken for electrical equipment cabinet. All cabinets and racks are closed except ventilation and cable inlet and outlet. The depth of each cabinet can ensure appropriate equipment and wiring space. Each cabinet has the same depth, height and color for each specific group.

2. Ventilation

All electrical components or devices shall be able to operate continuously in the enclosure used and in the specified environment. The cabinet is provided with proper natural passage. The heat generated by the dispersed equipment is protected by mesh or foam barrier through the mouth to prevent sundries from entering. The shell shall be pressurized and sealed, and the air inlet shall be over leakage.

3. Cable in and out

Cable holes shall be reserved in the factory according to the required positions, and removable plates shall be provided for final processing on site. The outer diameter, laying mode and sufficient bending radius of the cable shall be considered at the inlet and outlet of the cable, and the cable fixing device shall be provided.

4. Cabinet door and maintenance panel

The door and panel design has enough rigidity, the door and panel can be disassembled for maintenance, and the panel is equipped with dust seal. All enclosures and panels shall be painted with baking paint after thorough removal of grease and rust.

5. Identification

The component marks in the equipment cabinet shall also be permanent marks, and temporary paste marks or pen identification marks shall not be used. The size of the name plate and the sign is large enough, and the documents of the name plate and the sign can be seen clearly at a distance of 2 meters under normal light.

6. Information bag

A data bag is hung inside the main door of each cabinet shell, which is used to hold the data or drawings of various electrical components or devices, wiring, repair and maintenance of the electrical equipment cabinet.

6、 Design and construction requirements of silicon cabinet room

1. Design requirements

1) Because the thyristor will emit a lot of heat when it works, in order to ensure the normal operation of silicon, the silicon chamber must be equipped with separate air conditioning system and ventilation equipment;

2) No. 10 channel steel frame is set under the SCR, power supply cabinet and field lamp cabinet;

This figure shows the installation of distribution cabinet base

3) The wall of silicon chamber needs to be shielded with steel mesh and separate protective ground wire to prevent interference from external equipment;

4) The floor load requirement of dimming and distribution room is 500kg / m2;

5) See the construction drawing for hole size of cable tray passing through floor and wall;

6) After the cable tray is laid, all holes shall be sealed with refractory materials.

2. Equipment and wire selection

1) In order to make the dimming distribution room orderly and beautiful, the distribution panel and dimming silicon cabinet should be uniform in size and color;

2) The moulded case switch is cm type. Because the third harmonic of dimming system is large and the potential deviation of neutral point is serious, it is suitable to select 4-pole switch in three-phase circuit. However, there is no switch with N pole twice the current of phase pole, so only 3-pole switch can be selected;

3) As there are many cables and it is difficult to lay, zr-bvr-500v conductor is required to be used from dimming distribution room to socket box, and zr-yjv-1kv cable is selected for conductor from distribution cabinet to dimming silicon cabinet.

3. Wire and cable laying

1) The conductor in the lighting distribution room shall be laid under the elevated floor.

2) The wires from the lighting distribution room to the socket box are laid along the bridge. Due to too many cables, if they are laid together, the size of the bridge will be too large and the laying path will be difficult to solve. Therefore, the cables from the lighting distribution (dimming cabinet) room of the Grand Theater should be divided into several groups of bridge.

(Figure A)

(Figure B)

Figure A and Figure B show the cable laying from silicon cabinet to socket box

4. Installation of silicon cabinet

The installation of silicon cabinet shall meet the design requirements. When it is difficult, appropriate adjustment can be made according to the position of cable trench and junction box; the base of rack shall be fixed with trench channel steel; the silicon cabinet shall be installed vertically with vertical deviation of no more than 0.1%; several racks shall be installed side by side, and the panel shall be on the same plane and parallel to the reference line, and the front and rear deviation shall not be greater than 3 mm. For the equipment arranged in a row with a certain interval from each other, the front and rear deviation of the panel shall not be greater than 5mm; the installation of the equipment and components in the silicon cabinet shall be carried out after the positioning and reinforcement of the silicon cabinet, and the equipment installed in the rack shall be firm and upright; the fixing screws, gaskets and spring washers on the silicon cabinet shall be firm and shall not be omitted.

Figure A Figure B

Figure B

Figure a shows the installation of silicon cabinet and B shows the installation of silicon cabinet

5. Construction quality requirements

1) Construction preparation and process quality control:

The quality management of engineering project is carried out in strict accordance with GB / t19001-is02000 quality standard. In the preparatory stage of construction, we plan the quality, construction period and cost objectives of the project, and formulate "the project quality of stage lighting system will reach excellent standards". Equipment, raw materials, finished products and semi-finished products are high-quality brand products with a pass rate of 100%; the first-time acceptance rate of the project is 100%, which ensures that the project creates a stage lighting quality engineering award. Among them, the fine rate of installation of lighting equipment and stage lamps is 100%, the allowable deviation rate is above 90%, and the score of Engineering perception quality is above 95 points. The first time acceptance rate of unit project is 100%, and the satisfaction rate of user complaint handling is 100%. To achieve the quality goal of "striving for high quality project", we have organized and established a reasonable and effective project management team and quality management team. According to the provisions of Hunan Provincial Construction Committee on eliminating common quality problems, we have formulated quality assurance measures, guided the way with samples, established model houses, and adopted a number of advanced technologies to guide engineering construction. With the strong support and cooperation of Party A and the supervision unit, we do a good job in technical safety disclosure, three handover inspection, and implement management points point by point. Through communication and coordination with the design unit, the general contractor and other relevant construction units, the project quality objectives are reached by all parties, and the necessary safety technical disclosure and quality inspection are carried out to jointly promote the project management level and ensure the realization of the quality objectives.

This project is for the construction of stage lighting engineering. In view of the tight schedule of Yueyang culture and Art Exhibition Center, it is difficult to coordinate among various construction units and there is no complete working face. We have specially formulated the organization and technical scheme for the construction of stage lighting engineering, reasonably arranged the sequence of construction departments and the construction quality of each construction team. The safety officer explained the second The construction site safety precautions of each team shall ensure the quality and construction period under the premise of ensuring safety.

As the main structure of the exhibition center needs a lot of electric welding work to install the bracket of light bridge, we do a good job in technical disclosure according to the requirements of the construction specifications, strictly control the welding parts of the support and steel structure, and the welding personnel work with certificates, and the full-time quality inspectors shall inspect whether the welding points of the welding parts are full and whether the steel melting is up to standard, There is no false welding and all kinds of supports are installed firmly and reliably.

The installation of trunking and conduit of the project shall be conducted in accordance with the requirements of national specifications. The direction of trunking and conduit shall be arranged in order, with clear layout and clear identification; the connection positions of all trunking and conduit transfer boxes shall be connected by special grounding connecting line to ensure the safety and reliability of grounding protection; the installation process of socket box, terminal box and signal box shall be unified to eliminate skewness; the opening parts of all trunking and conduit transfer boxes of the whole stage lighting shall be sealed without any Omission, to ensure that signal lines, cables are not damaged by small animals such as mice. Special attention should be paid to the treatment of the burr at the edge of the cable slot in order to catch up with the schedule. Special inspection should be carried out on all the joint parts of the trunking. All the exposed metal openings and edges are provided with protective openings and protective rings. The phenomenon of scratching the cable sheath during cable laying is eliminated, and the insulation of all signal lines and cables is in good condition and up to standard.

Due to the large number of stage lighting circuits and relatively concentrated cable laying, we have adopted the method of double identification at both ends for each cable. The wires in the silicon cabinet box, terminal box and socket box are straight, with strict color separation, and the number identification with black characters on white background is used to ensure that the wiring is not wrongly connected. In the construction, in addition to the technical disclosure in accordance with the national standards, in the actual cable laying, the method of laying in layers is adopted in the large-scale trunking with dense cable laying. The method of multi-layer laying and multi-point fixation is used to make the cable in the trunking get better heat dissipation. At the same time, according to the characteristics of the exhibition center, we will Power supply of ups and stage lighting should be ensured in case of power failure.

In order to facilitate the owner's use of the stage lighting signs, we adopt the method of dual function identification. For all lighting circuits, we use a set of corresponding numbers of light path number cabinet silicon number socket number which are identified by serial numbers. At the same time, we also use a set of serial numbers corresponding to function, cabinet silicon and socket number one by one, so as to facilitate the use of beginners and further understand the distribution of lighting circuits in various parts. In the parts that are not easy to observe, such as light suspenders and hanging cages, we enlarge the serial numbers of the seats and paste them beside the sockets, which is more convenient to view; for the circuit distribution of each cabinet, we can make it easier to check, We also have a detailed drawing pasted in the silicon cabinet room, and a general drawing marked with serial numbers in the lighting control room, so that it can be seen at a glance and is very convenient for preliminary users, maintenance and repair.

All materials entering the site shall be provided with certificates and test reports, and shall be used only after passing the sampling inspection as required. The mandatory standards shall be strictly implemented in the construction.

2) Effect of construction quality:

Self evaluation of technical quality assurance data of the project: all the basic works, wiring concealed works, lamp control room, dimming silicon room stage lighting equipment installation engineering, lighting bridge installation engineering, lighting network equipment installation engineering, lighting equipment debugging engineering, connector installation engineering are all qualified.

The supervision unit organized each unit to carry out the intermediate acceptance for each division, and the quality evaluation grade of each division of the project was excellent. They are: basic engineering, lighting bridge installation engineering, wiring concealed engineering, lamp control room, dimming silicon room stage lighting equipment installation engineering, lighting network equipment installation engineering, connector installation engineering, lighting equipment debugging engineering.

3) Safety and civilized construction management:

Our company strictly controls the construction safety, establishes and implements the safety production responsibility system, compiles the plan of "safe production and civilized construction" and implements it conscientiously. A safety supervision group is set up on the construction site, safety officers are set up in the team, and the new workers enter the site for education. The safety activities and study before the shift are strict. There is no quality and safety accident in the whole construction process from the commencement to the completion of the project. Due to our company's effective management of safe and civilized construction, the final project safety rating is excellent.

4) Contract performance:

The project shall be completed within the time finally determined by Party A according to the contract scope.

Chapter 5 stage lighting system debugging

For the equipment debugging, because of the different conditions of each project and the equipment used are not the same, it is difficult to unify a general method, which needs to be carried out by separate categories and projects, so as to control the debugging process of lighting engineering as completely and comprehensively as possible.

1、 Preparation before commissioning

The commissioning of lighting engineering is a work that requires both technology and experience as well as conscientious and meticulous spirit. When the design and construction meet the requirements, the commissioning is unreasonable and not meticulous, which not only can not achieve the design effect of the project, but also may make the equipment work in an abnormal state. Therefore, we should fully realize the importance of this work before debugging.

Before commissioning, it is necessary to carefully confirm whether each equipment is installed and connected correctly, and carefully ask the construction personnel about the problems left over by the construction that may affect the use; before commissioning, carefully confirm whether each equipment is installed and connected correctly, and seriously ask the construction personnel about the problems left over by the construction that may affect the use; before debugging, you must read all the equipment instructions carefully again Make sure that there is no problem with the power supply line and voltage before commissioning; ensure that the relevant personnel on site before commissioning; prepare corresponding instruments and tools before commissioning.

Inspection of installation, power supply line and connection

Because there are many connection points and connectors involved in the whole system of lighting engineering, errors may occur due to individual reasons during installation. Therefore, careful inspection is necessary. The general inspection includes the safety of equipment installation, whether the power supply line is reasonable, whether the connection of various connectors is correct, etc. in addition, there is an important inspection item: careful inspection Whether the state setting of each equipment meets the design requirements must not be forgotten. Otherwise, it is easy to damage the equipment, whether the power selection switch of each equipment is appropriate, and whether the address code of the computer lamp and color changer is set correctly.

After the above construction steps are sure to be completed, the commissioning of the equipment should be ready.

2、 Debugging of lighting control system

For the complex lighting system of theater style studio, because it involves the lighting of characters and stage settings and different lighting styles, the debugging of this aspect includes the color tone, color, color temperature, brightness, projection range, dimming stage scene, sequence program editing and other aspects of the content, which can not be easily debugged by general practical engineering, in which the control The debugging of the system is the key to the project debugging. The system involves the most equipment, the most debugging parts and the most possible problems. Therefore, we should concentrate on completing it first. Instruments and tools to be prepared: ammeter, DMX generator, oscilloscope, multimeter, network cable corrector, insulation testing instrument, etc.

Debugging steps

From the signal source, gradually check the signal transmission. This inspection is very meaningful, because only when the signal is well transmitted in each equipment, can the dimming silicon cabinet, computer lamp, color changer and other equipment get a correct and stable signal, and can have a good control quality. Therefore, when doing this step, we must be patient and careful, Do not rush to connect the dimmer cabinet, computer lamp, color changer and other equipment, and the relevant peripheral processing equipment should also be placed in the bypass state. According to the construction drawings, the inspection should follow the direction of the signal, and gradually check its level setting, positive and negative polarity and unblocked condition, so as to ensure that each equipment can get the best signal provided by the former equipment and also provide the best signal for the lower level. While checking the signal, it should also gradually check its level setting, positive and secondary polarity, and smooth condition Smooth condition, to ensure that each equipment can get the best signal provided by the former equipment, and also can provide the best signal for the lower level equipment. While checking the signal, we should observe whether the equipment works normally and stably. The significance of this work is that when a single equipment fails or is unstable, it is more convenient to handle and will not endanger the safety of other equipment Therefore, this inspection should not be carried forward to the next step.

After the network circuit is checked to be correct, the dimming silicon cabinet, computer lamp, color changer and other equipment are connected to the system one by one. Under a small load, first check the dimmer cabinet, computer lamp, color changer and other equipment one by one to prepare for the following debugging:

1. Debugging of dimming silicon cabinet:

First pull out all the silicon drawers to ensure that the circuit of the output circuit is cut off, and check the connection point of the power line. It is required to be firm and seamless, and the contact point is reliable. Use a multimeter to measure whether the three-phase five wire power supply is correct. Then, use the insulation detection instrument to test the insulation degree of the wire to meet the safety standards. Inform the power supply department to supply power. After the power is connected, use a multimeter to measure the power supply If the voltage is in line with the voltage, use the oscilloscope to measure the AC waveform of the power supply, and there is no distortion. After careful inspection and test, turn on the power supply of the processor, and check whether the LCD display content is correct according to the manual. After confirming that there is no problem, the silicon drawer is inserted one by one for single circuit debugging. After all 48 silicon drawers and 96 thyristors are inserted, the debugging is qualified Set the address code of the dimming cabinet, turn off the power supply of the dimming cabinet, and debug the next dimming cabinet according to the same procedure.

2. Debugging of network computer dimming table:

1) First of all, carefully check whether all equipment is installed in place and there is no hidden danger of safety and performance;

2) Ensure the normal power supply and reliable connection of each equipment;

3) Carefully check the separate operation status and network backup function of each dimmer;

4) Centralized storage, q-field storage call, effect lighting;

5) Storage and transfer of hard disk and floppy disk;

6) The overall function configuration is complete and in strict accordance with the technical requirements of the contract.

3. Debugging of computer lamp:

First of all, it is necessary to carefully check the separate operation of each equipment. The bulb and coated glass of computer lamp are required to wear cotton gloves for installation, and direct hand contact is not allowed; finally, the installation should be firm, the protection measures should be complete, and the safety must be absolutely guaranteed. Because the internal control system and mechanical parts of the computer lamp are relatively precise, the lighting power consumption is large, and the protection measures are relatively perfect, so if the internal control elements or bulbs are damaged due to transportation or installation reasons, the computer lamp will not work normally. However, it is more troublesome to confirm the fault cause of this kind of computer lamp in the complex lighting system Before connecting or installing the system, check the condition of each equipment separately, so as to check the lamps and control console.

The lighting should be set correctly. It can be said that all computer lights can work normally only under the correct settings. Therefore, if the unit and system are in a normal and orderly state, the correct setting is very important. The setting contents include: the control mode of lamps, the power supply mode, the movement range, the address of lamps in the system, and the processing of control line terminals The location setting is often wrong in engineering, and its setting is based on the selection of address code, that is, dip switch on the lamp must be carried out in strict accordance with the form provided in the product manual, and can not act rashly.

The most important feature of computer lights is that they all need to have corresponding control equipment. The computer lamp console can control the operation. If the console is set unreasonably or fails, the computer lamp will not work normally, or even can not work. Especially, the control equipment of complex lighting system plays an important role in the normal work of lighting, so it is necessary to set the equipment, The setting contents include: control form, output mode of control signal, model and quantity of lamps and lanterns, content of control program software, etc.

4. Commissioning of color changer:

1) Carefully check whether the external connection of the color changer is correct and whether the appearance is a new machine;

2) Strictly comply with the technical requirements of the color changer in the contract;

3) Whether the power on operation is stable, whether the color is synchronized, and whether the color change speed is coordinated.

5. Stage lighting debugging:

1) Carefully check whether the external connection of stage lamps is correct and whether the appearance is new;

2) Check the operation condition of single lamp and the whole operation condition carefully;

3) Strictly comply with the technical requirements of stage lamps and lanterns mentioned in the contract.

After the completion of the above items, it is necessary to check whether the operation speed of the network computer dimming table and computer lamp console is consistent with the action response time of on-line controlled equipment such as lamps, computer lights, color changers, cigarette machines, etc., and whether the computer lights, color changers, and cigarette machine self check are normal. There are also: to pay attention to the light system, sound system and video system interference with each other. If there is, record the time when the interference occurs and the model of the specific equipment, so as to solve the problem in the future.

3、 Overall commissioning

When the commissioning of each project has been completed, and it is confirmed that each equipment is in good condition and there is no obvious improper debugging, it is necessary to start the comprehensive debugging of the whole system. Different from the separate test of each equipment and each system, the comprehensive overall debugging has no specific adjustment parts, and its main task is to check the mutual relations among the systems during the coordinated operation Whether the working parts of the light system are coordinated, whether they will produce mutual influence and interference when they work together, and whether the dimming action in the lighting system will interfere with the sound system, etc.

4、 System simulation test run

After the commissioning of all the equipment, the process that must be carried out before the formal operation is the simulation operation of the system. Because the scale of Yueyang culture and art exhibition center is relatively large, and the working state is also different, it is difficult to find the hidden dangers or deficiencies in the short-term project commissioning. However, once the project is completed, the actual system operation time will be much longer In the past, there was the phenomenon of over time and overload operation. At that time, the hidden dangers and deficiencies existing in the system that had not been found may expand rapidly, bringing adverse effects to both users and the project. Simulation operation is to understand the working conditions of the system, find problems and prevent them in a similar actual operation environment.

First of all, ammeter should be used to measure the current of each phase of the power supply line when the equipment of each project is running separately and in general. Although in the design and construction of the power supply line for the corresponding requirements, the current distribution of each phase also has a general understanding, but the actual operation situation and the theoretical value will certainly be different, in order to achieve a clear understanding, absolutely safe, the actual operation of the current situation must be measured.

If there is a big gap between the actual measured value and the theoretical value, or there is a large gap between the current distribution ratio of each phase, or the abnormal phenomenon of line current, the rectification must be carried out again to ensure the safety of power consumption.

Secondly, it is necessary to check the working stability of each equipment in full load operation and long-term operation.

Finally, check the heating condition of each equipment in full load operation and long-term operation.

The equipment of lighting system is basically power consuming equipment, and there will be different degrees of heating in operation, especially the load of silicon cabinet, computer lamp and other high-power equipment. The heating situation is relatively obvious, so the heating phenomenon to a certain extent will not have any impact on the use of equipment and the safety of system and equipment. However, if proper cooling space is not reserved during the installation, or the heat dissipation of the equipment itself is not good during long-term and heavy load operation, it should be solved. Otherwise, the light equipment will be protected, and the heavy one will cause equipment damage. In general, if the equipment is heated seriously within the normal working range, the equipment must be replaced; if there is no suitable cooling space and the heat of the equipment is large, forced ventilation should be considered, and the owner should be informed clearly that dust cleaning and equipment maintenance should be carried out regularly.

Since the simulation operation is very important and necessary work, each work at this time will be the long-term stability of the equipment and the safety of the system work. Especially the heating condition of power supply lines and equipment will directly affect the safety of the project, so all engineering and technical personnel must attach great importance to it.

Because there are many items to be debugged, set and inspected in lighting engineering, and these results and problems are important reference materials for future use and maintenance, it is necessary to record the results and problems in each step of work, and then make necessary analysis and summary. The useful record data for users should be handed over to them, and the useful record data for future maintenance should be properly kept by the designer. The recorded results include: the location number of the equipment, the setting state of the equipment, the test data during debugging, the information of relevant program editing, etc.; the recorded problems include: the problems of equipment working environment, equipment interference, equipment operation status, etc.

5、 Conclusion

Just as the stage lighting system has been debugged, the opening ceremony and evening party of 2008 Hunan Economic Cooperation Conference and the second Hunan business conference, the first Yueyang culture and Art Festival and Yueyang campus culture and Art Festival have been staged in 1200 large theaters and 400 small theaters in Yueyang culture and Art Exhibition Center. Let's share the wonderful moments:

Figure A Figure B

Figure B

Figure C Take yueyang.com

Figures a, B and C show the opening ceremony and performance of the 2008 Hunan Economic Cooperation Conference and the second Hunan business conference

Hunan industry promotion and major project signing ceremony of 2008 Hunan Economic Cooperation Conference and the second Hunan Business Conference

Figure A

Pictures A and B show the scene of the newly compiled historical story drama "today's Yueyang Tower"

Figure A

Figure B

Pictures A and B show the scene of blue romance, a large-scale global music stage party

Figure A

Figure B

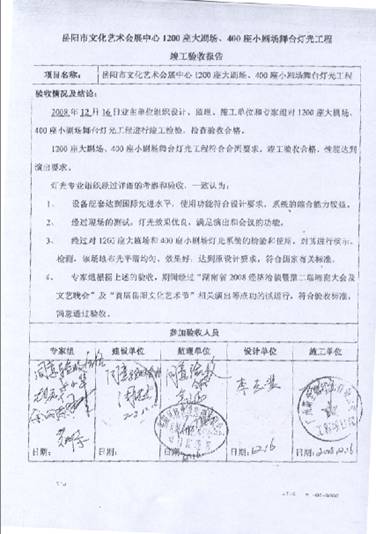

1. Summary of stage lighting system project completion acceptance report: the equipment matching has reached the international advanced level, and the system comprehensive ability is strong; the lighting effect is excellent and meets the functional requirements.

2. Media review

Changjiang information news: on the evening of November 21, Yueyang cultural and Art Exhibition Center Grand Theater was full of splendor, dreamlike, and immersed in elegant atmosphere. The Symphony Orchestra of the Central Opera House came to perform for the first time. Jasmine and other well-known Chinese and foreign tunes gathered around the beam, which again and again aroused the warm applause of more than 1200 audience. Yueyang is a famous cultural city with a history of 2500 years. Its rich cultural heritage, like the surging river, moistens the residents of this city.

In recent years, Yueyang City has continuously strengthened cultural construction and activated the urban context. One by one literary and artistic works, a batch of artistic talents, enrich the cultural expression of the city, Zhang shows the literary talent of the city, and gradually improves the soft power of the city. "Cultural prosperity" is one of the goals of Yueyang City. The holding of the first cultural and Art Festival is not only a powerful measure of the municipal Party committee and the municipal government to promote the great development and prosperity of culture, but also a concentrated display of Yueyang's cultural soft power. At the same time, we are also showing the new cultural card of Yueyang as a famous historical city.

The city culture highlights Yueyang's "soft power". China Oriental Song and dance troupe performs in the first-class exhibition center in China.